WE GUARANTEE

Quick response to Customer's enquiries and wishes

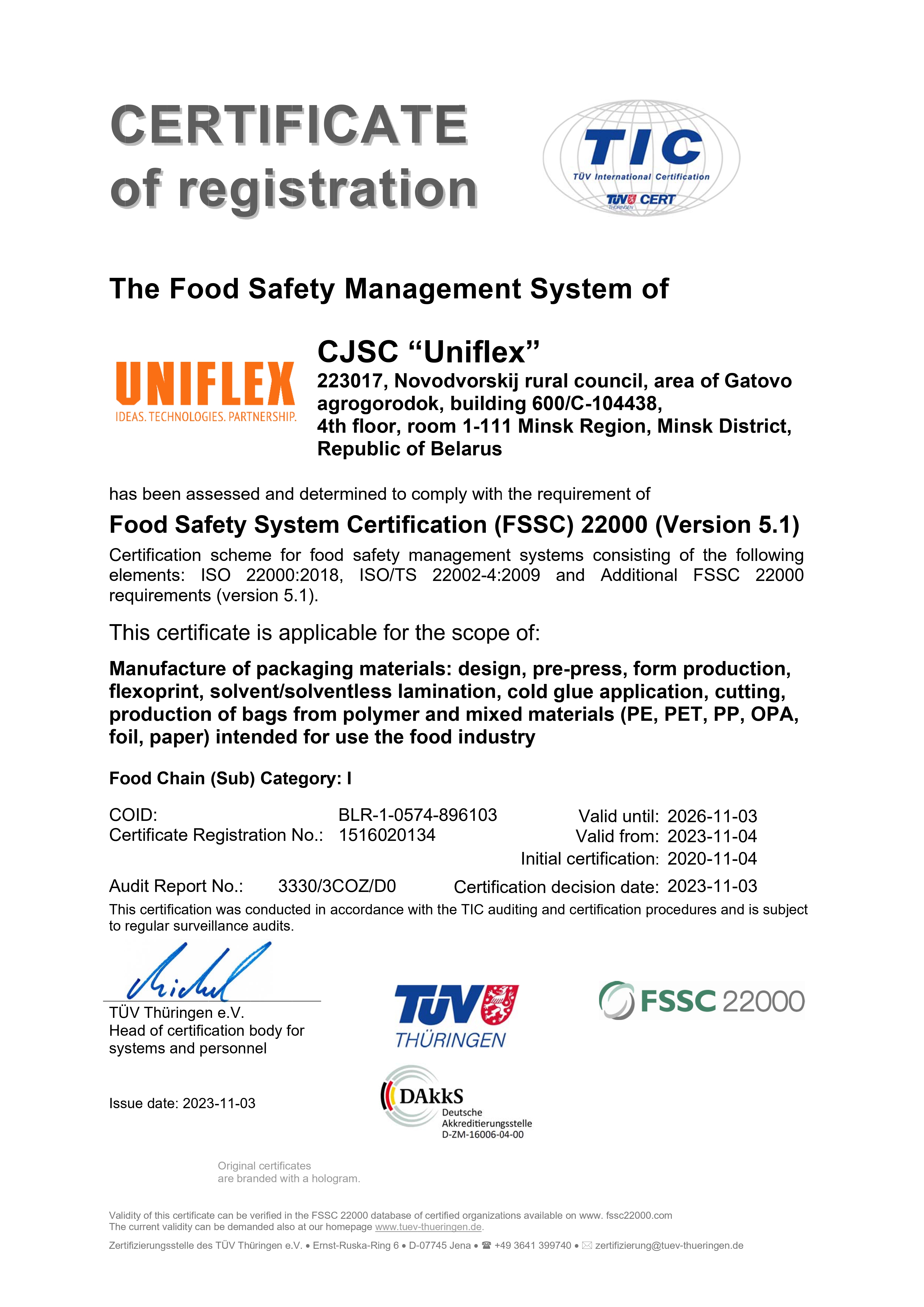

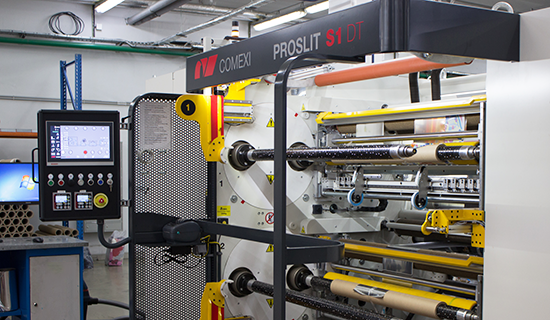

Well-structured business processes, stable work and highly-qualified staff

Efficient procedure of the contract analysis

Precise information about the terms of product readiness

Expert advice on materials to best suit the features of your product and technical requirements of the packing line

Technical support during the tests of packing and labelling materials at the Customer's production lines

Competitive market prices